|

Transform Solar Revolutionizes Monocrystalline PV

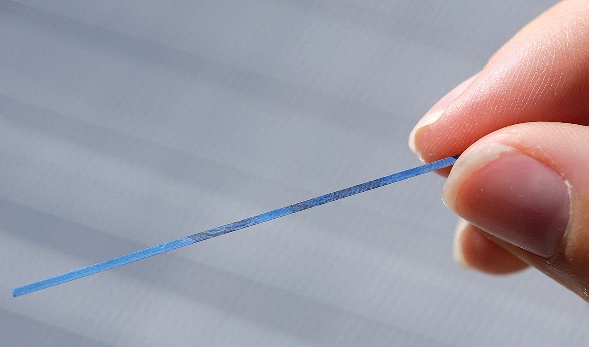

There’s plenty of innovation headroom left in monocrystalline silicon. Exhibit A: Transform Solar and their new Sliver Technology series ultrathin, bifacial monocrystalline cells (one of which is shown below).

Currently crystalline silicon solar panels are made from flat cells, which are laid out horizontally to form a panel. This approach takes about 5 to 6 grams of silicon to produce 1 watt of electricity. Transform Solar has turned crystalline solar cell on its head … literally, with their vertically mounted ultra-thin monocrystalline solar cells and in the process reduces the amount of silicon required to <2g to produce 1 watt of electricity.

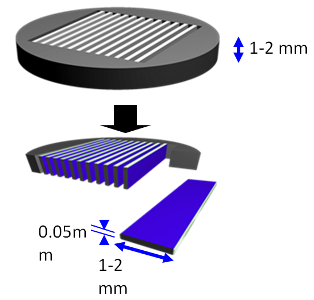

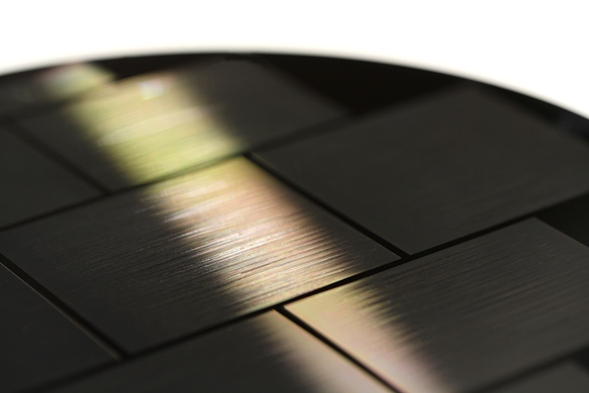

This new approach, utilizes a proprietary micromachining method to form deep vertical grooves in a 200mm wafer, from which come ~5000 millimeter or two wide, <50µm thick cells, fabricated within the wafer frame.

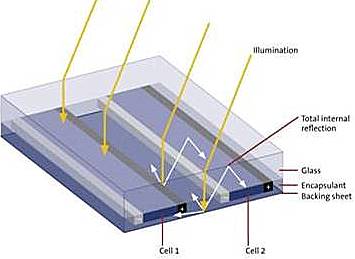

The super-thin, elongated cells are then harvested, put into subassemblies, and laid out in modules, with carefully spaced gaps that help maximize light capture on both sides of the cell surface.

The process uses at least 80% less silicon than other c-Si approaches. Current generation silver solar cells use <2g of silicon per watt, with a roadmap to reach 1g. This compares to 5 or 6g per watt for SunPower or Evergreen cells.

The design scheme calls for each triple-redundant, reverse-bias-protected cell, rated at about a half-volt each, to build up voltage in an interconnection web that requires very low current and thus puts less stress on the panel and reduces the chance of failure—thereby boosting reliability. Additionally, the new Sliver Technology PV Panels are able to perform better than traditional crystalline solar panels in two of the commonly found environmental conditions that lower solar output levels – namely shading and heat.

Unlike conventional crystalline solar panels that can exhibit a sharp drop in overall performance when shadowed, Sliver Technology ensures the panels continue to output power from most non-shaded banks. The secret is in the panel architecture. The company builds "banks" of cells by connecting hundreds of cells in series, and then connects the banks in parallel. Not only does this add reliability, it also ensures that the impact of shading on panel performance is virtually proportional to the area impacted by the shading. This is critical in installations where fouling can occur; or where trees, roof-fittings, or buildings can regularly shade parts of the panel, impacting electrical current.

The cells run cooler and have a lower thermal coefficient than most competitive products, according to Transform, with the Sliver Panel Series IV datasheet stating a nominal operating cell temperature (NOCT) value of 39.6°C.

With the new "cell bank" strategy (typically 10 or are typically included in a full module) Transform Solar would have the ability to organize these banks in a variety of sizes, shapes, and voltages – giving it the ability to meet challenging architectural requirement. Another advantage is the flexibility that is possible. Did you say flexibile? Who ever thought monocrystalline silicon solar cells could be flexible? Well that's exactly what's possible with the Sliver Technology.

The component was quite bendy, though not foldable, reminiscent of flex modules from CIGS companies such as Ascent, SoloPower, and Global Solar or the venerable Uni-Solar amorphous-silicon laminates. While the company currently puts the subassemblies together during a post-cell processing, mid-production step and then assembled on a fairly standard conventional moduling line in a traditional rectangular unit … the flexiblilty of the solar cells gives them the possibility of adapting to a variety of shapes as may be required on a major architectural project.

Before Origin ever got into bed with Micron, it had taken Sliver down the testing/reliability and certification path for several years, subjecting the 25-year-warranty panels to rigors well past the standard environmental test protocols. (Certain IECs and ULs are pending, but should be approved soon, according to the company.) The unique features that create high reliability for our Sliver panels include: Built-in reverse bias protection dissipates any reverse current flow across the cells, making them fundamentally more tolerant to adverse electrical events. Each cell has triple redundancy with multiple points of interconnection, delivering built-in protection for the panel. Small cells have low current and are connected in series via multiple interconnects; these interconnects carry a current that is orders of magnitude lower than conventional crystalline panels, leading to less stress and a lower likelihood of failure. Parallel banks of cells provide greater tolerance to partial shading which reduces unwanted power dissipation in shaded cells.

The mayor of Boise said that Boise had entered into lease negotiations with Sunergy World to build a $45 million, 10MW solar power plant on city-owned property (the location of the former city dump actually) west of the airport. He went on to say that the project will use modules from Transform Solar to be installed on ground-mount arrays from Sun Storage, with the juice to be sold locally under a power purchase agreement.

Not only has Transform Solar come out with an innovative advance in the crystalline solar market. They have the wherewithal to bring it to market. Transform Solar is a 50/50 joint venture between heavyweights Micron Technology and Aussie power generators Origin Energy. The company officially launched in January and kept very quiet about their plans, but around June of 2010 – a story leaked out that they were actively setting up a production line in an abandoned Micron technology plant site in Boise, Idaho. The initial 20MW phase of the production ramp is in full swing inside a converted 200mm semiconductor fab in Boise, while the final module assembly line resides at another repurposed Micron site in nearby Nampa. (Tech development continues to be based in Australia, where Origin first researched and developed Sliver.) Phase 2 will push capacity to >300MW in the former chip fab, with room to grow to >650MW elsewhere on Micron’s campus when demand warrants a third phase of expansion. The necessary facilities, infrastructure, and workforce are already in place, and the corporate couple have a few dollars in the bank, what with combined revenues of about $11 billion and market capitalization several billion north of that figure. Given Micron’s prowess in cranking out memory and other chips by the gazillions at a competitive cost and high yields, it may be a bit premature to bet against Transform’s chances in the realm of cheap silicon processed for high-end solar cells, even in the crowded PV module marketplace. For more about Transform Solar's Silver …. Including a video how the new Sliver Technology solar cells are made -- click here. Photos courtesy of Transform Solar

|